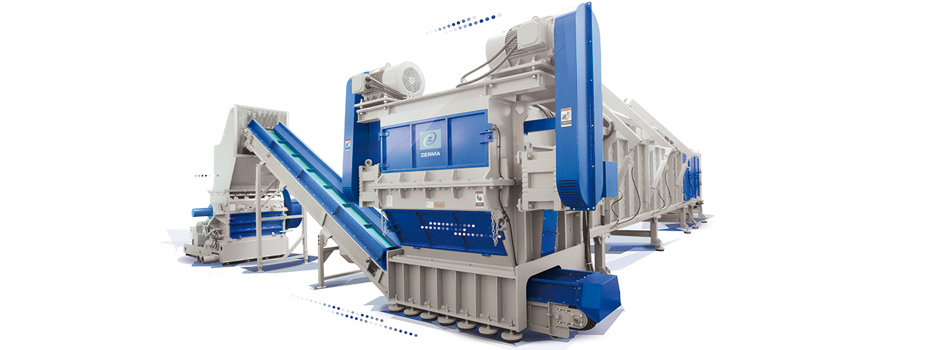

Single shaft shredders

The right machine

for todays recycling needs

Well thought out solutions

ZERMA extended its product portfolio from granulators and pulverizers to include single shaft shredders in order to cover a wider range of applications. Shredders can be used in a wide range of applications apart from plastics they can be used for wood, paper or MSW recycling.

ZERMA offers the following machine series:

- ZBS

- Affordable shredder for lumps and purgings

- ZSS ZPS ZIS

- Dependable allrounder

- ZHS

- Horizontal shredders

- ZXS

- Heavy Duty shredders

- ZRS

- Shredder for long lengths of large diameter pipes

As with all ZERMA machines the shredders are easy to operate and maintain. They are dependable and deliver high quality output.

- Rugged construction

- Low speed - high torque

- Easy ton integrate with other ZERMA machines

ZBS – affordable shredder

for lumps and purgings

- Affordable solution for small lumps

- Simple upgrade for existing granulation system

- Easy to move and place

- Tangential infeed avoids the need for a hydraulic pusher

- Small footprint

- Low energy consumption

ZSS / ZPS / ZIS –

dependable allrounders

All shredders in the ZSS/ZPS/ZIS series use a dual speed hydraulic to ensure high efficiency when shredding different types of products.

Oversized bearings and shafts ensure a long service life. Hydraulic screen cradles and PLC controls are standard on all machines to make maintenance easy. The machines can be tailored to various applications with options such as rotor cooling or different knife and screen designs.

The ZPS shredders feature a larger ram than the ZSS machines and are better suited for heavy applications such as pipes.

The ZIS series shredders feature an internal ram to increase the cutting chamber volume without increasing the footprint. They are very well suited for large hollow products such as barrels or IBCs.

- Low speed, high torque gear drive

- Powerful hydraulic swing type pusher

- Proven well engineered design

- Smaller footprint compared to traditional shredders with horizontal pushers

- Bolted in drive shafts

- Multiple rotor designs and materials

- Two speed hydraulic comes standard

ZHS – horizontal shredders

The ZHS horizontal shredders are single shaft shredders featuring an angled hydraulic ram suitable for a wide range of material shapes and sizes. The ZHS shredders are equipped with a 600 mm diameter E style rotor and knife fixing system. The roller guided hydraulic ram makes feeding of large heavy walled materials possible without the risk of jams, blocking or excessive wear on guide rails. Like all ZERMA shredders the ZHS series can be tailored to individual requirements, this includes different drive powers, knife configurations as well as discharge options.

- Large feeding hopper

- Robust welded steel construction

- Low speed operation

- Advanced rotor / knife mounting system

ZXS – Heavy Duty Shredders

The ZXS shredders are single shaft shredders with a powerful two speed swing ram design eliminating the risk of blocking and wearing out of internal guide rails. The machine is very versatile and can be used for shredding of all kinds of input materials and is well suited for different industries. The 750 mm diameter rotors ranging from 1500 to 3000 mm width are driven by two oversized gearboxes. The low speed of 45 rpm guarantees a high torque and smooth operation. The hydraulic power pack is well integrated into the machine housing to save space and protect it from damage but still easy to access or remove for maintenance

- Low speed, high torque gear drive

- Powerful two speed hydraulic swing type pusher

- Heavy Duty design+ High throughput rates

- Suitable for very large and heavy parts

- Big diameter rotor (750 mm)

ZRS – shredder for long lengths

of large diameter pipes

The ZRS shredders are the worlds first single shaft shredders able to handle large diameter pipes up to 1200 mm without the need for pre cutting. Since their introduction they became the per se standard for pipe shredding and are used by the leading pipe manufacturers all over the world. More than 100 installations demonstrate our technological leadership in this industry and continuing innovation based on market demands and customer feedback.

- No pre cutting of pipes of up to 1200 mm diameter necessary

- Virtually risk free, automated operation

- Elimination of amperage peaks

- High throughput rates

- Feeding of bundles or nested pipes and profiles

- Big diameter rotor (up to 1500 mm)